AMB Hardware

Robust Magnetic Bearings

Waukesha Magnetic Bearings collaborates closely with customers on the design and development of turbomachinery to ensure that bearing performance is optimized to the application. Our robust bearing designs have provided high reliability over a wide range of sizes, pressures, loads, temperatures and operating environments.

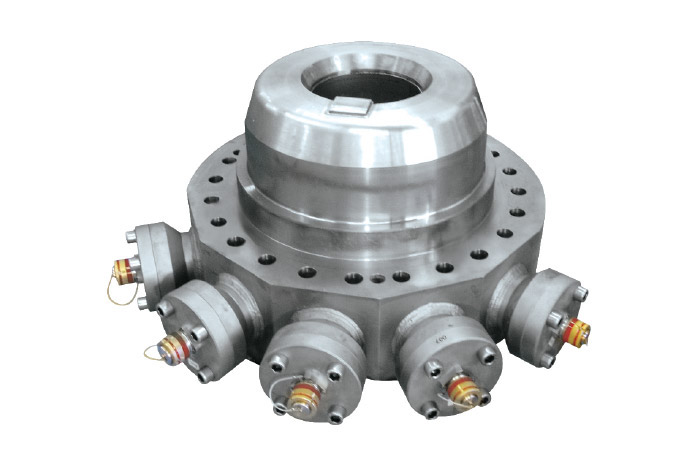

Our sealed magnetic bearings can be immersed in mildly corrosive process fluid environments, while our industry-leading canned magnetic bearings are designed for immersion in the most extreme corrosive and abrasive environments.

Hardware Components

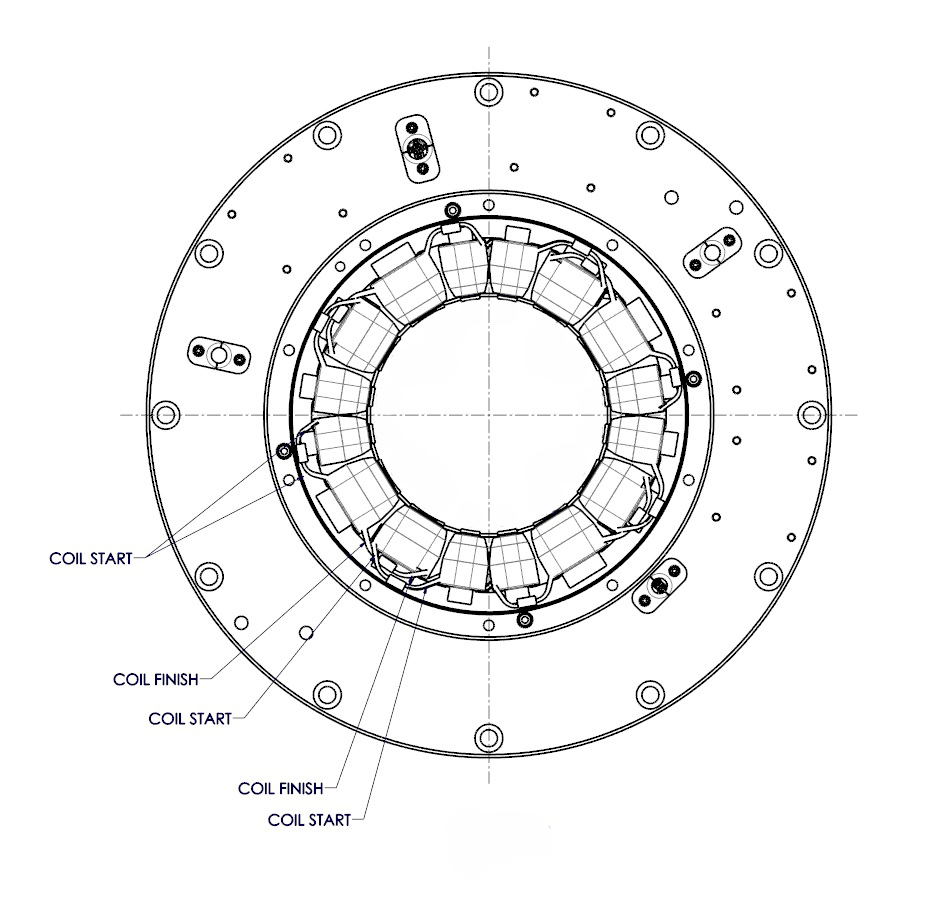

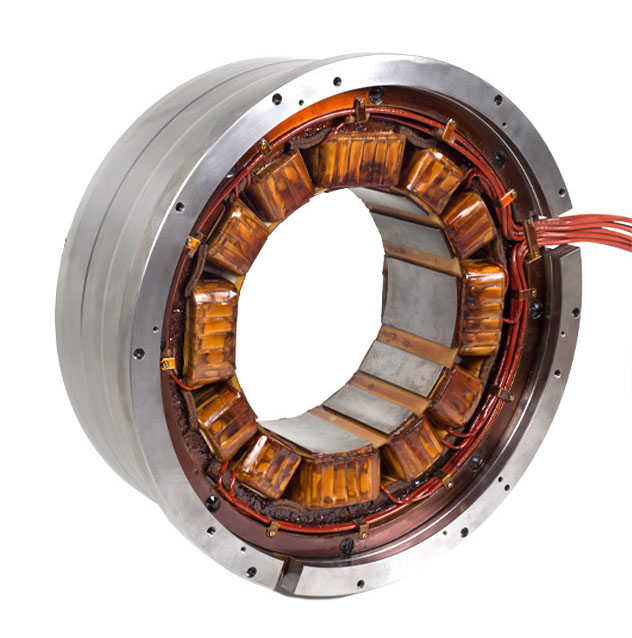

AMB system hardware typically includes radial bearings, axial bearings, position sensors and auxiliary bearings.

Sealed Magnetic Bearings

Sealed bearings are designed to be immersed in a process fluid environment and are ideal for mildly corrosive environments and applications requiring high reliability and availability.

Rotor and stator laminations are made of corrosion resistant alloys or more conventional alloys protected with specialized coatings.

The sealed magnetic bearing stators and sensors have all windings, conductors and connections encapsulated for protection against liquid content. Liquid-resistant auxiliary bearings are available with these systems.

Magnetic Bearing Controllers

Waukesha Magnetic Bearings controllers employ complex control algorithms for optimized system performance and efficiency. In addition, remote connectivity capabilities allow for remote commissioning, monitoring, diagnostics and adjustment.

Support and Service

While the conventional approach to commissioning and maintenance requires onsite support, Waukesha facilitates these remotely and trains customers to perform many routine functions. Waukesha can also perform AMB system upgrades to extend plant operating life and improve reliability and efficiency.