Marine

Engineered to Address Challenges at Sea

The marine industry demands high levels of performance and reliability, whether in the propulsion system or ship-service power generation.

Waukesha Bearings has been supplying the industry since the mid-1960s, serving maritime vessels ranging from small tugboats to container ships to large oil tankers. We pioneered and continue to supply complete bearing systems for stern tubes, drive systems (main propulsion and shaft line), gearboxes and reduction gears.

Waukesha Bearings combines its engineering expertise, proven designs, and precision manufacturing with a deep understanding of ship issues, developed through years of service to the maritime and naval industry. The result is a system-based analysis and optimized bearing for your vessel’s specific requirements.

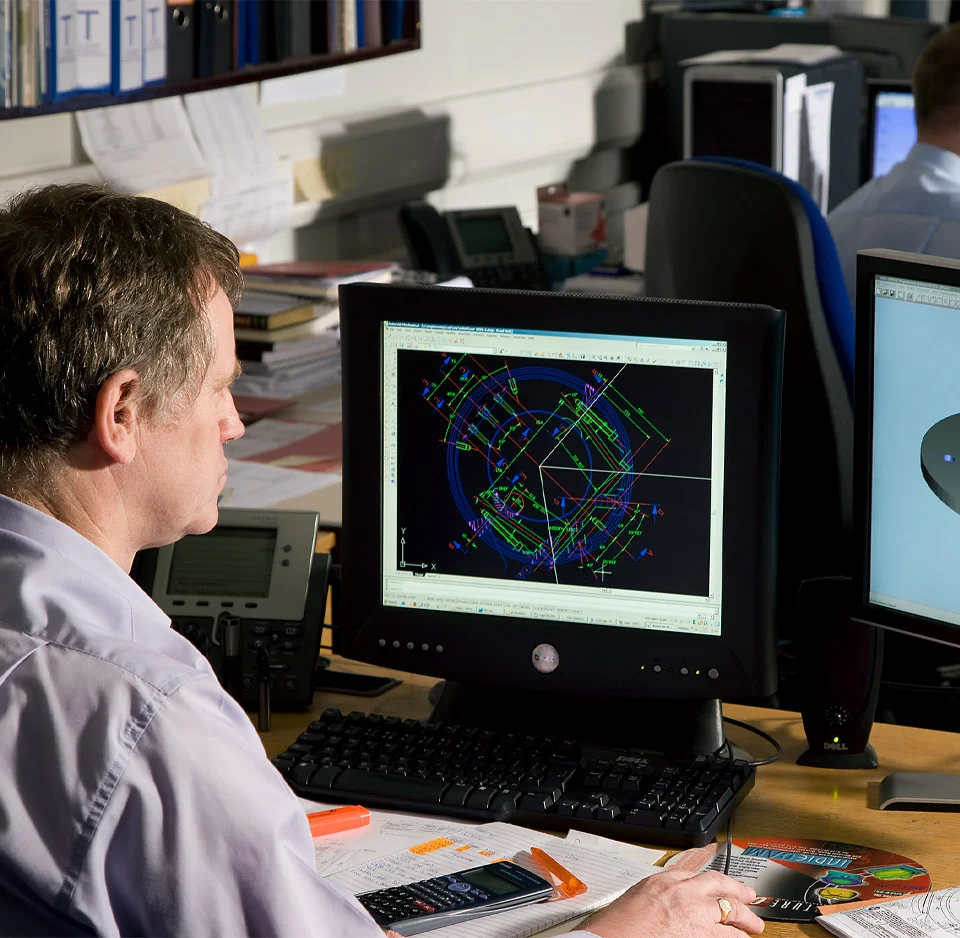

System-Based Engineering

Waukesha Bearings excels at solving complex problems. Our engineers examine conditions up and down the shaft to ensure that we provide the right solution for your requirements and your system. Cross-coupling effects and potentially destabilizing forces are evaluated together to get a complete picture of equipment performance.

With the available envelope, anticipated operating conditions, and bearing requirements, our team of experts designs optimum thrust, journal and combination bearings, backed by reliable performance predictions.

We then integrate that bearing with the necessary housing, instrumentation, lubrication system, cooling system, seals and more for a complete, coupling-to-coupling solution.

Custom Engineering, Integrated Solution

Waukesha Bearings combines engineering and manufacturing expertise, a robust supply chain, rigorous quality inspections, and FAR and DFARS proficiency to provide a complete solution and ensure maximum performance.

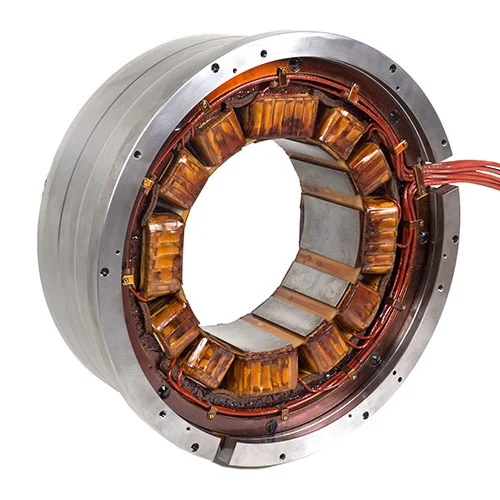

Waukesha Bearings designs and manufactures each bearing to the space and load requirements of the customer. Our capabilities include pedestal mounted, bulkhead mounted, and flange/foundation mounted thrust bearings; fixed geometry journal bearings; self-aligning tilt pad journal bearings; and combination journal/thrust bearings.

Quality Second to None

Marine bearing manufacturing is centralized in our Wisconsin facility, where we have decades of experience in the unique requirements of the marine industry, including proficiency in United States military standards and specifications and NAVSEA technical publications.

To maintain quality control, the babbitting process is performed in-house. Tin-based babbitt is applied centrifugally to journal bearings and via static pour for thrust pads. The babbitt is metallurgically bonded to the bearing for maximum operating efficiency, and all materials meet or exceed the specification and standards established for shipboard use.

Waukesha Bearings performs non-destructive testing, including ultrasonic, liquid penetrant and visual inspections, to ensure product integrity. In addition, solutions can be designed for shock loads.

Marine Bearing Solutions

Tilt Pad Journal Bearings

Tilt Pad Thrust Bearings

Combination Bearings

Magnetic Bearings

Downloads

- Marine Bearings Information Sheet

- Modern Bearing Design and Practice (The Institute of Marine Engineers)