Flexure Pivot® Journal Bearings

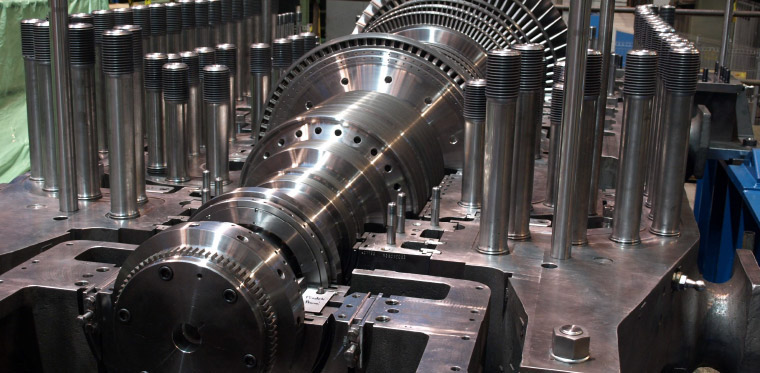

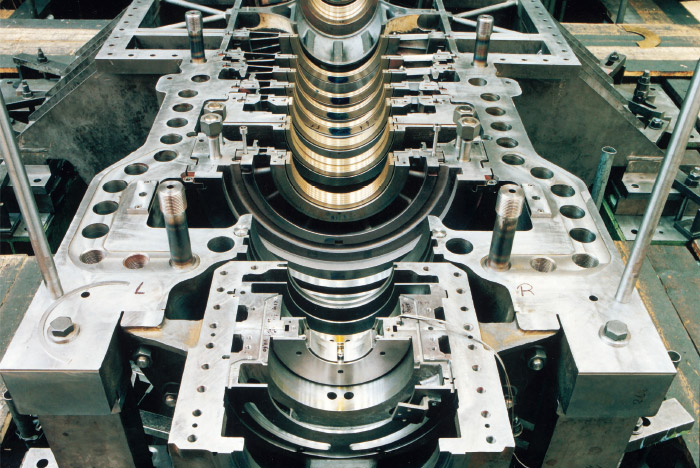

Flexure Pivot tilt pad journal bearings achieve high stability while eliminating pivot wear, high contact stresses and pad flutter than can affect conventional tilt pad designs.

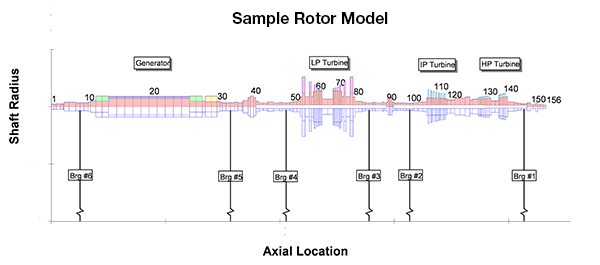

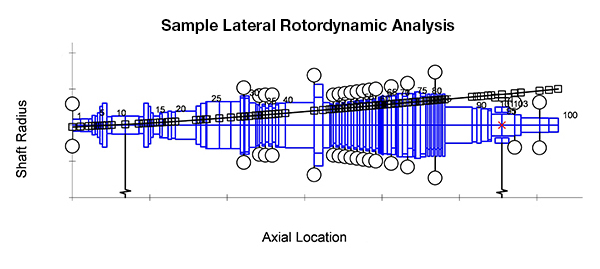

Waukesha Bearings utilizes comprehensive rotordynamic analysis to validate original builds for OEMs and to diagnose problems and propose the right solutions for end users.

Along with the rotor, the bearings and seals are the most influential components in rotating equipment vibrations. Therefore, the accuracy of a rotordynamic analysis relies on the analyses of the bearing and seal characteristics.

As a global leader in the engineering and manufacturing of bearings and seals, Waukesha Bearings has the most reliable and accurate tools to perform those analyses.

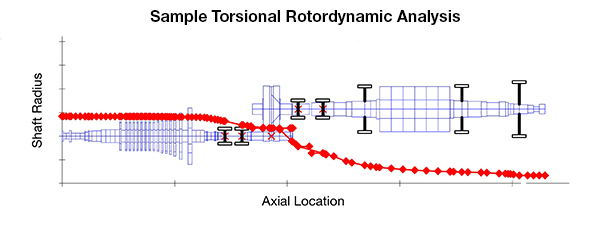

Our industry-leading analytical tools include transfer matrix, polynomial transfer matrix and finite element–based rotordynamic analysis tools.

The accuracy of our analyses and predictions allows us to optimize the dynamic characteristics of bearings and seals for individual operating systems to ensure optimal performance.

Torsional, axial and lateral vibrations can each affect the efficiency and reliability of rotating equipment. Torsional vibration is an angular vibration, or twisting, of the shaft. Axial vibration occurs along the axis of rotation, while lateral vibration occurs perpendicular to the axis – side to side or up and down or both.

Upon receipt of the relevant information, our engineers build a rotor model and analyze the bearings and seals using proprietary codes. The customer receives a comprehensive report of the findings, based on the type and scope of analysis performed.

For a power generation customer in Scandinavia, Doosan Škoda Power engineered a 46 MW steam turbine as part of a combined cycle system. When high subsynchronous vibrations forced a trip in turbine operation at just 27 MW versus the rated 46 MW, a rotordynamic assessment confirmed the cause of the vibrations and informed an effective solution.