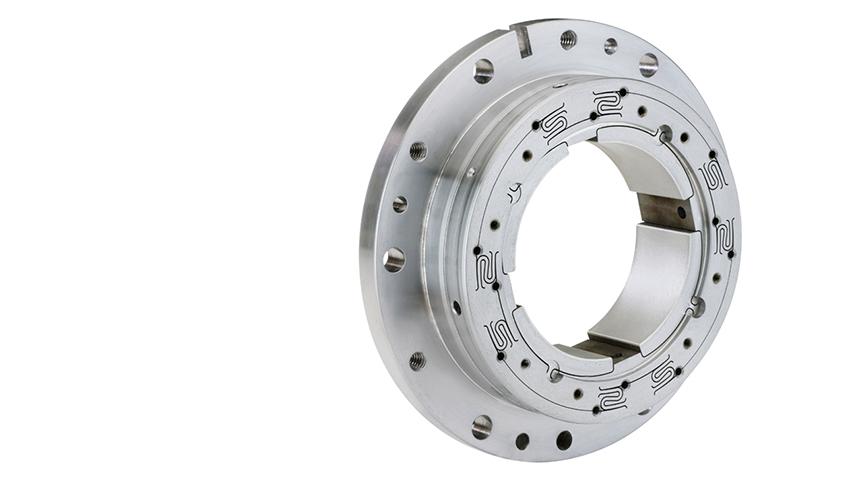

Integral Squeeze Film Damper

Leading Vibration Solution

ISFD® technology provides highly engineered damping and stiffness to allow exact placement of critical speeds and increase the dynamic stability of rotor/bearing systems.

In the patented ISFD design, stiffness and damping are independent of each other and can be precisely controlled. This produces higher and more accurate damping capability than a conventional squeeze film damper and makes ISFD technology a leading solution for controlling vibrations in mainstream and emerging applications.

Stiffness and damping are each optimized for the application through rigorous rotordynamic analysis.

Improve Stability

By introducing flexibility into the rotor/bearing system and providing optimum damping, ISFD technology maximizes the energy dissipation at the bearing locations and significantly improves the stability of the system.

Shift Critical Speeds, Reduce Amplification Factor

ISFD technology can shift critical speeds and significantly reduce the amplification factor. With the reduction in amplification factor, machine seal clearances can be tightened to reduce gas or steam leakage.

Reduce Dynamic Bearing Forces

ISFD technology reduces the dynamic load that is transmitted to the bearings, which reduces pedestal vibration and increases bearing life, particularly for rolling element bearings. For fluid film bearings, the technology can mitigate pivot wear and reduce babbitt fatigue.

Decrease Unbalance Sensitivity

ISFD technology helps reduce the sensitivity to unbalance, protecting impellers and seals from rubbing and increasing maintenance intervals.

Versatile Design

The ISFD design, manufactured through electrical discharge machining (EDM), can integrate the bearing and damper into one unit for a space-saving solution suitable for new and retrofit installations. ISFD technology can be used with tilt pad, Flexure Pivot® tilt pad, fixed profile or rolling element bearings.

High Power Density Applications

As turbomachinery is designed to higher pressures and speeds for hydrogen and supercritical CO2 (sCO2) applications, the integration of ISFD technology will be a critical enabler to achieve journal bearing peripheral speeds above 130 m/s.

The precise placement of critical speeds and control of rotor modes will help address potential destabilizing forces in the system and minimize unbalance response.

Features

- Precise stiffness and damping

- Drop-in replacement without modifications to housing

- Shaft-centering ability

- Split configuration availability

- Constant stiffness and damping over a wide range

- No cavitation

- Suitable for use in tilt pad bearings, fixed profile bearings and rolling element bearings

The Role of Damping

Damping decreases vibrations by removing energy through resistance to motion. For rotating equipment, damping is necessary to control vibrations and prevent them from damaging the rotor, bearings or other components in the machine.

Related Case Studies

ISFD Technology Eliminates Subsynchronous Vibrations

Typical Applications

- Integrally geared compressors

- Centrifugal compressors

- Steam turbines

- Gas turbines

- Turboexpanders

- Radial turbines

- Supercritical CO2 power turbines

- Generators

- Motors

- Overhung process equipment