Optimized performance for wind applications

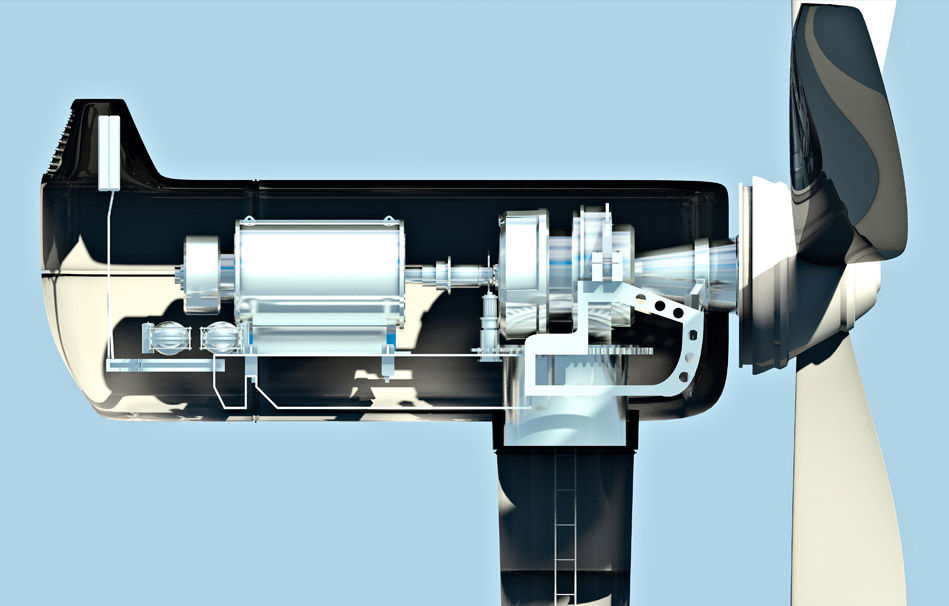

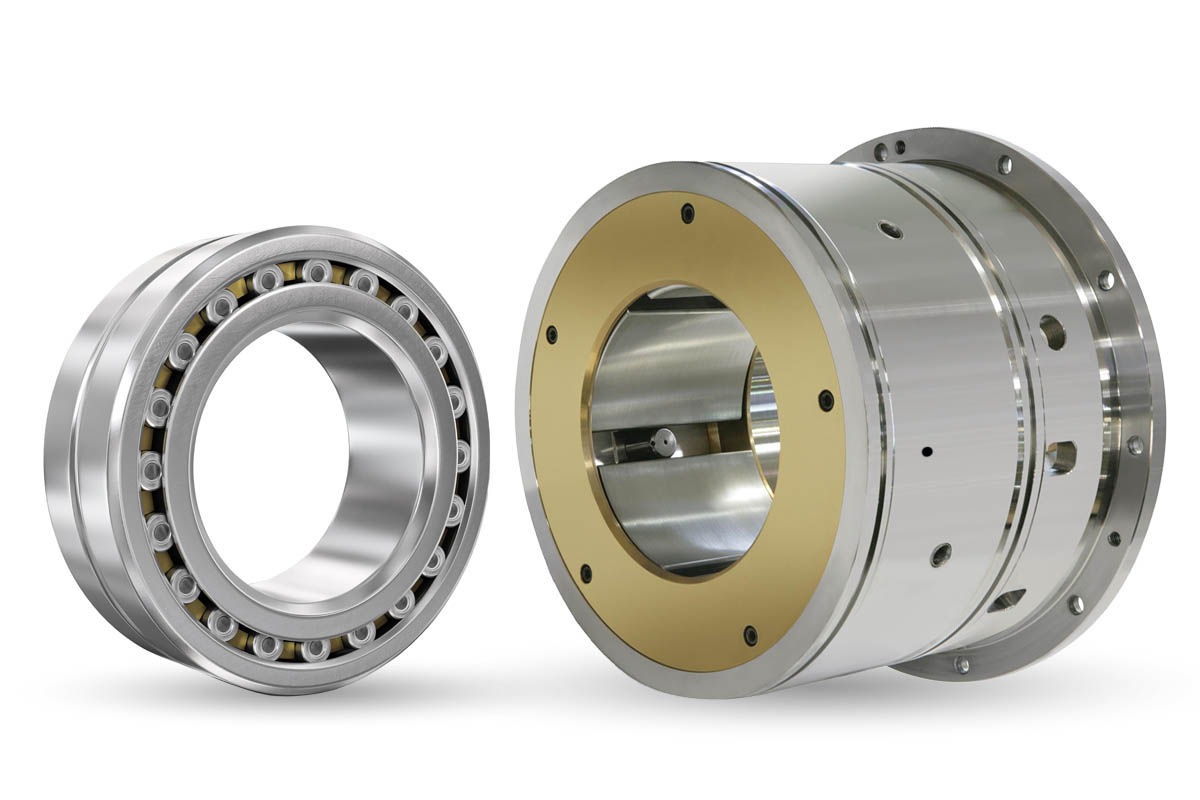

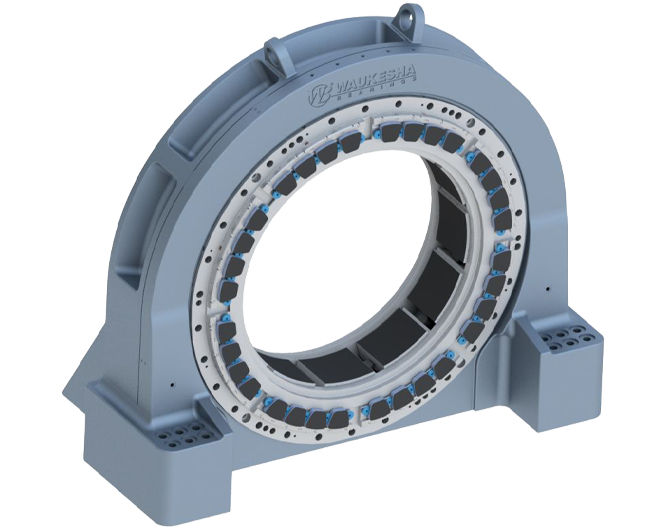

To remain competitive, wind turbine operators must find ways to optimize equipment performance, increase reliability, and reduce maintenance costs. Waukesha Bearings collaborates with equipment OEMs and leverages world-class material development and testing capabilities to design main shaft fluid film bearing solutions optimized for wind applications. Our modular design can scale up to fit larger wind turbines, resulting in cost savings. The optimized pad shape easily integrates into the nacelle and provides advanced bearing performance within a broad range of operating conditions, including assembly, low speed/idling, and extreme events.

Benefits of fluid film bearings for wind main shaft bearing applications:

- Easy assembly process

- Reduced failure rates

- Unlimited bearing lifetime

- Low sensitivity to wear

- Easy exchangeability -- no crane needed

- Tolerant to high cyclic and dynamic loads

- Limited maintenance required