News

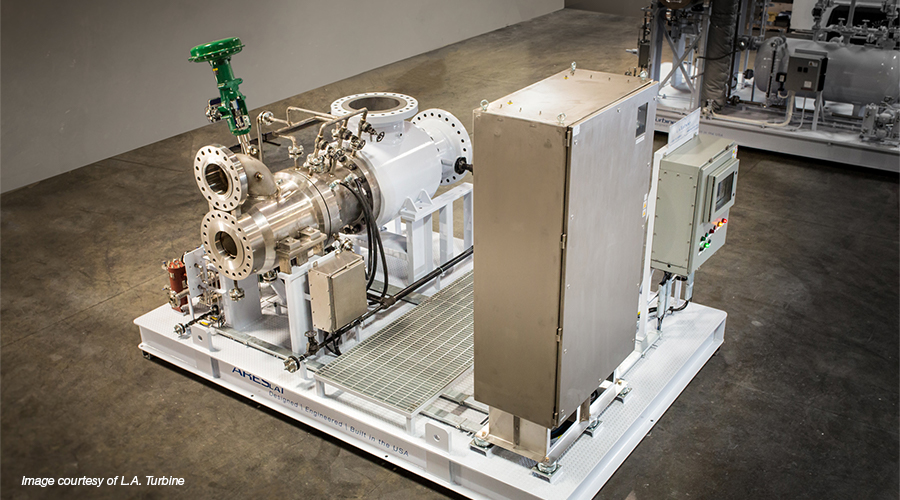

L.A. Turbine Releases ARES AMB Turboexpander-Compressor with Industry’s First Skid-Mounted AMB Controller

VALENCIA, CA — L.A. Turbine (LAT) today announced the release of the first ARES Active Magnetic Bearing (AMB) turboexpander-compressor designed for a 200MMSCFD gas processing plant. The ARES AMB Turboexpander features the industry’s first skid-mounted AMB control system and programmable logic control (PLC) panel, made possible due to engineering and technological innovations resulting from a partnership between L.A. Turbine and Waukesha Magnetic Bearings. Gas processors immediately benefit from lower CAPEX, faster commissioning, decreased maintenance, greater site layout, temperature and performance flexibility, a smaller footprint, and a more environmentally friendly machine.

Until now, AMB controllers needed to be installed in a building away from the skid installation site. This required additional capital investments, specialist labor costs and time. With the new ARES AMB design, the control system is installed directly on the turboexpander skid and is ready for operation upon delivery to the site. Plus, operators benefit from the ability to perform remote commissioning, monitoring and tuning of machine performance due to the high-tech digital signal processors and control algorithms of the Waukesha Magnetic Bearings Zephyr® 5-Axis Controller. The adoption of magnetic bearings results in lower property, plant and equipment costs overall. Not only are capital costs decreased but future costs diminish due to the elimination of ongoing maintenance for auxiliary systems. Continuing technological advances like the on-skid controller increase the scalability of magnetic bearings to make them more accessible for all customers.

L.A. Turbine’s ARES line also includes the ARES Oil Turboexpander-Compressor featuring an oil bearing auxiliary system. Both configurations are standardized, another industry-first, and are designed for gas processing plant capacities of 60/120/200/300MMSCFD. In less than one year, L.A. Turbine engineers took a product concept and delivered the ARES Turboexpander line—engineered, crafted, assembled and tested it—all within the walls of L.A. Turbine’s 90,000 square foot manufacturing facility.

“ARES AMB is the result of a great partnership between two companies who are flexible, knowledgeable and innovative. L.A. Turbine’s vertical integration resulted in an expedited R&D process and the delivery of a final product in record time,” said L.A. Turbine President, Danny Mascari. “We truly feel our ARES AMB Turboexpander-Compressor gives us a competitive advantage within the U.S. market. It is a natural choice for EPCs and operators looking to capitalize on the current and future growth of the U.S. gas processing industry. It’s a quick-to-market, financially beneficial and leading-edge technology that is adaptable based on market economics–an all-in-one turboexpander solution made in the U.S.A.”

“Collaboration with customers is at the center of our magnetic bearing solutions,” commented Marcell Ulrichs, President of Dover Precision Components, the parent company of Waukesha Magnetic Bearings. “We are proud to bring our team’s expertise and development capabilities to our partnership with L.A. Turbine. Together, we have provided an innovative technology solution that gives gas processing plants multiple advantages.”