Babbitt Bearings

Proven Bearing Material

Tin-based babbitt, also referred to as whitemetal, has long been a standard for oil-lubricated fluid film bearings.

Babbitt is a soft metal that exhibits excellent conformability, compatibility and embedability, allowing the bearing to bear the brunt of potential damage, instead of the more expensive shaft. It is considered a forgiving and rugged material and is widely used for both fixed profile and tilt pad bearings.

Babbitt Backing

Babbitt bearings are more accurately babbitt-lined, with steel or copper chrome (CuCr) backing.

Due to the high thermal conductivity of copper chrome, CuCr-backed babbitt runs cooler and experiences less thermal distortion than steel-backed babbitt, thus increasing the bearing’s load capacity.

Depending on application requirements, steel and CuCr backing may both be used in the same bearing.

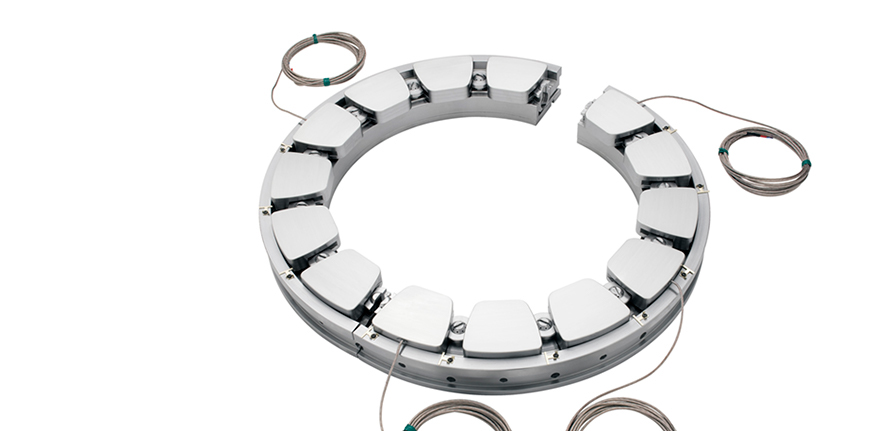

Babbitt Thrust Bearings

With non-equalizing and self-equalizing tilt pad designs, as well as fixed profile configurations, Waukesha Bearings delivers expertly engineered thrust bearing solutions.

Babbitt Journal Bearings

Waukesha Bearings delivers babbitt bearings in sleeve and tilt pad configurations. Every bearing is optimized to application-specific performance requirements.

Advanced Material Options

As machine loads, speeds and temperatures increase, the main limitation for a bearing is frequently the bearing’s surface temperature. Typical industry practice is to limit the maximum operating temperature of babbitt bearings to 130°C (266°F) because babbitt loses strength at elevated temperatures.

Babbitt also has a relatively low fatigue strength compared to advanced materials. In extreme cases of dynamic loading, low fatigue strength can result in premature bearing damage.

Alternative fluid film bearing materials are available to accommodate more challenging operating conditions.

Intro to Bearing Materials

The selection of the bearing materials plays a significant role in the performance of fluid film bearings. Load, speed, operating temperature, insulation requirements, and lubricant type and cleanliness may all play into the material choice.

Download our “Introduction to Fluid Film Bearing Materials” for an overview of material characteristics, benefits and limitations in fluid film bearing use.