Automated Commissioning

Take Control of Commissioning

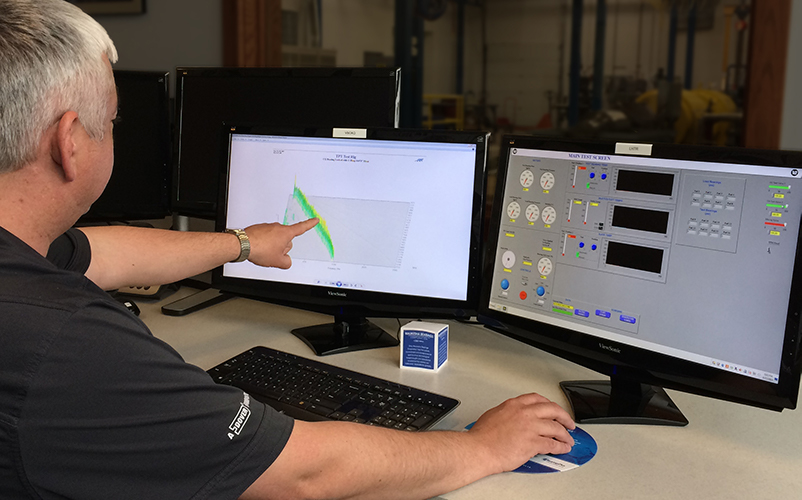

With Automated Commissioning, Waukesha Magnetic Bearings puts the power of commissioning in the hands of its customers.

Commissioning is traditionally done by the magnetic bearing supplier, but with Automated Commissioning the OEM or end user can commission their own solution, giving them full capability on the equipment they operate.

Total Cost of Ownership

Automated Commissioning speeds up commissioning, provides automatic checks after maintenance, generates performance insights from commissioning records, and overall, provides the customer with cost savings.

Advantages for OEMs

- Ability to commission independently

- Ability to maintain independently

- Faster commissioning on first of class

- Rapid commissioning for repeat units

- Options for remote support by AMB specialists

- Automated commissioning record

- Consistent commissioning process

- Consistent tuning for repeat units

- Reduces need for AMB specialists

Advantages for End Users

- Automatic checks after maintenance – independent of suppliers, meaning reduced downtime

- Faster commissioning for reduced site time and cost

- Automated commissioning records for rapid identification of machine performance degradation

- Consistent tuning for repeat units

- Reduced need for dedicated, specialized support

- Options for remote support by AMB specialists

- Simplified process for matching the OEM factory build

Integration with AMB Controllers

Automated Commissioning is available on Waukesha Magnetic Bearings digital controllers. Older NGC controllers are upgradeable on a case by case basis.

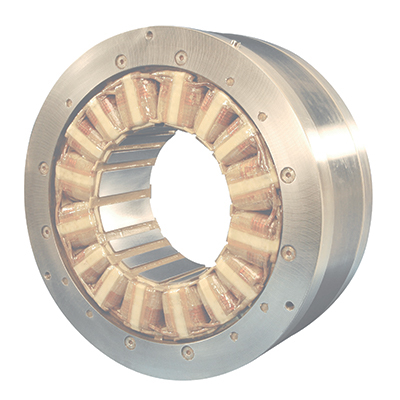

Digital Magnetic Bearing Controllers

- Zephyr controller – for machinery in the power range of 1 to 18 MW

- Chinook controller – for machinery in the power range of 10 to 25 MW

- Elephanta controller – for machinery in the power range of 15 to 80 MW