Chinook Controller

High-Power Digital Controller

Available as a single- or dual-bay cabinet, the Chinook® controller is a high-power digital magnetic bearing control system recommended for rotating machinery in the power range 10 MW to 25 MW.

The controller provides simple and fail-safe integration of the control cabinet with the machine station via digital output/input, and its high processing performance allows for complex algorithms that provide high dynamic efficiency and noise immunity.

The controller also offers an automated commissioning and tuning process, built-in condition monitoring and remote adjustment capabilities.

Advantages

- Proven availability exceeds 999.%

- Reduced maintenance cost with planned & predictive maintenance programs

- Automated Commissioning capability

- Built-in UPS for immunity to supply interruptions

- Capability of retrofit to magnetic bearings supplied by others

- Spares service and extended warranty option

- Comprehensive training program available

Chinook Controller Features

Configuration

- 5-axis control (option for 4-axis control)

Interfaces

- Door-mounted operator panel

- Hardwired discrete DCS interface

- Analogue diagnostic outputs

- PROFIBUS DP slave*

- MODBUS RTU or TCP slave*

- SOAP slave*

Control Law Capability

- SISO/MIMO controller with tracking filters

- Multi-coordinate control (MCC)

- Automatic balancing algorithm (ABA)

- Runout compensation

- Synchronous open loop feed forward

- Advanced amplifier algorithm (for canned bearings, software flux feedback)

Sensor Support

- Magnetic displacement

- Inductive, eddy current

- Capacitive

- Dual position sensor ring option

- Redundancy

- Flux feedback

Diagnostic Capabilities

- Web server interface

- High speed capture buffer

- Trend logging

- Event logging

- Automatic clearance check

- Integrated transfer function measurement

- Integrated spectra capability

- Integrated harmonic capture

- 3rd level trip

- Built-in tools show compliance with ISO sensitivity performance criteria

Other

- Support for purge protected bearings

* Available as an option

Certification

- CE

- CB

- TR-CU

Related Case Study

Magnetic Bearings Exceed 95% Availability in Pipeline

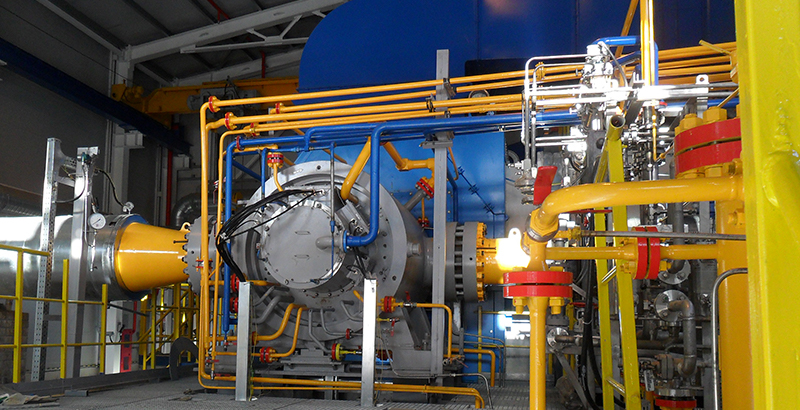

After bitter experience with other compressor stations in frigid locations, Gazprom sought ways to improve compressor operations. Our robust AMB systems, utilizing a dual-bay Chinook controller, were able to increase reliability and availability, as well as improve integration with the compressor station.

Typical Applications

- High-temperature gas-cooled reactor (helium use)

- Natural gas pipeline compressors

- Energy recovery flywheel

- Loop layer machine

- Sour gas with canned or sealed bearings