How Fluid Film Bearings Work

Operating Principle

In a fluid film bearing, the stationary and rotating surfaces are separated by a thin film of lubricant, such as oil, air, water or process fluid. In a hydrodynamic fluid film bearing, the film pressure that separates the surfaces is created by the relative motion (rotation) of the surfaces as the lubricant is pulled into a converging geometry between the surfaces.

No contact of the surfaces takes place except during start-up and shutdown.

Converging Geometry

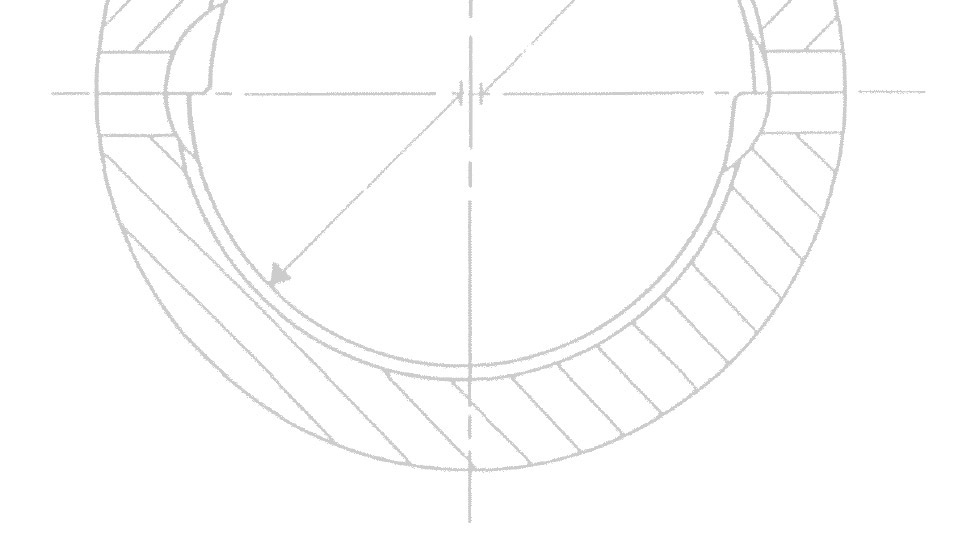

In the case of journal bearings, the converging geometry is provided by the slight difference in diameters of the shaft and the bore of the bearing. For improved static and dynamic performance, a defined profile can be machined into the journal bearing to develop the proper film. Journal tilt pads are often used if stability is an issue, if varying conditions must be accommodated or if other bearing performance parameters require optimization.

In thrust bearings, the converging geometry is either machined into the face of a fixed plate or provided by the tilting action of tilt pad thrust bearings. A fixed geometry is designed for a specific condition, so tilt pad bearings are often used to accommodate changing conditions.

The Role of Bearings

The primary functions of bearings are to control the rotor position, balance forces on the system, and provide damping.

Journal bearings support radial loads (perpendicular to the axis of rotation). Thrust bearings support axial loads (along the axis of rotation).

The materials and design of thrust and journal fluid film bearings are selected to optimize the bearing geometry for increased efficiency of the equipment and fewer demands on ancillary equipment.

Fluid Film Bearings vs. Rolling Element Bearings

A key difference between rolling element and fluid film bearings is the expected life of the bearings. Rolling element bearings typically have a predictable life based on the operating conditions (the calculated L10 life). Fluid film bearings, when properly designed and maintained, can operate for decades.

Fluid Film Journal Bearings

Waukesha Bearings supplies custom-engineered hydrodynamic fluid film bearings in both fixed profile and tilt pad designs. Bearing geometry and materials are carefully considered to provide minimum power loss and optimum dynamic performance for the given operating conditions.

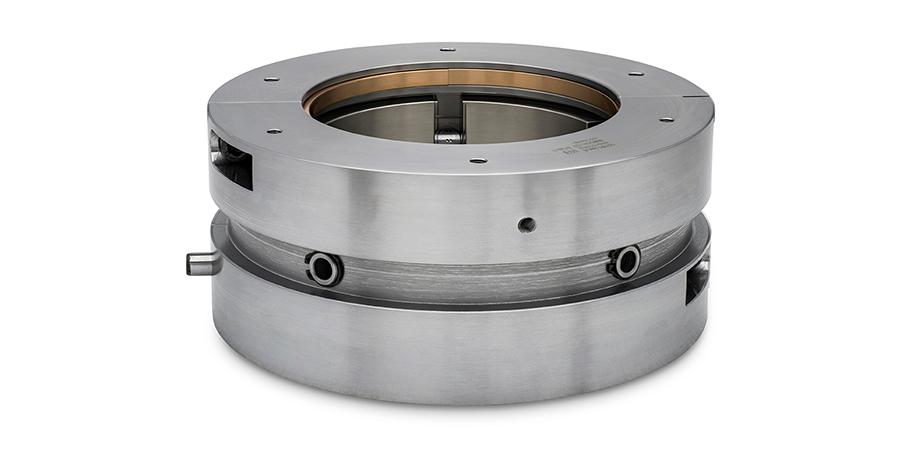

Fluid Film Thrust Bearings

Waukesha Bearings supplies hydrodynamic fluid film thrust bearings in fixed profile designs for lightly loaded applications and in equalizing or non-equalizing tilt pad designs for more demanding operating conditions.